Plastic gear transmission features and concepts

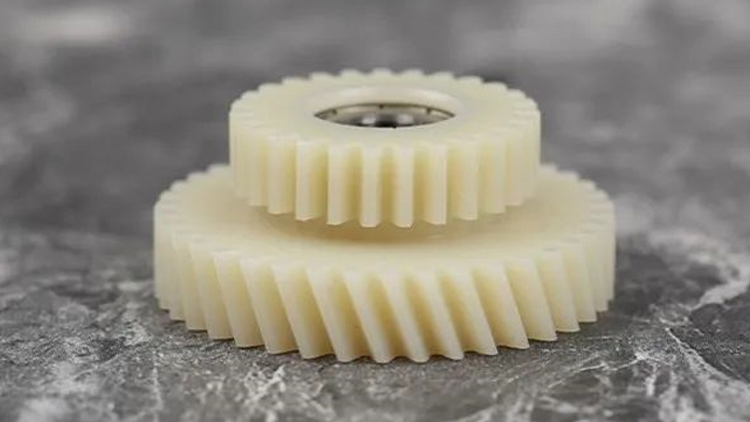

Gear transmission is one of the most widely used transmission methods in mechanical transmission parts, and plastic gears, as one of the gear products, are more and more widely used in various fields because of their light quality, low transmission noise, high temperature resistance of gears, and increasingly strong ability to withstand high loads. In the gear drive, the gear drive requires its accuracy, smoothness, and uniformity, especially for high-end machinery products that require higher gear accuracy.

An important feature of plastic products is the nominal wall, and the thickness of the nominal wall will affect the strength, cost, and accuracy of the part.

And gear products in the transmission process noise and heterodyne control is particularly important, the generation of heterodyne mainly with the radial runout of the gear, the tooth pitch accumulation error has an important relationship, but also with the shell center distance size position tolerance has a great deal of have South China fragrance. At the same time to know is that the production of the mold plays a decisive factor in the accuracy of the gear, mold production accuracy and processing methods and processing technology has a vital connection. With the development of science and the demand for lighter gear products, gears have changed from metal gears to plastic gears because of the need for better compatibility, durability and wear resistance, and the requirement for long life. And plastic gear grease can reduce noise, reduce wear, and extend life, among other properties.

The use of synthetic lubricant gear grease, along with the appropriate addition of extreme pressure additives and solid lubricants, will not only improve the load-bearing capacity of the tooth surface, but also improve transmission efficiency, and more extended gear life.

The plastic gear is essentially a plastic structural part whose primary function is the transmission of power and motion, so the plastic gear structure must follow the laws of both transmission part design and plastic structural part structural design for integrated design.

The gear teeth are an important working part of the transmission and are the core of the whole gear. The two aspects of gear design to be paid attention to are the tooth shape correction and the balanced tooth thickness. Tooth shape correction: When plastic gears are processed by the molding method, tooth shape relies on the shape of the mold cavity to ensure.

同时由于型腔多采用线割方式加工,因此不存在金属齿轮加工中的根切现象。

但是没有根切并不意味着齿形不会产生干涉,所以要保证塑料齿轮拥有良好的啮合齿廓就必须进行齿形的修正。