Kunpeng Electromechanical: Plastic gear manufacturer, injecting stable power into equipment transmission

The transmission core is urgently needed: plastic gears support the "operational skeleton" of the equipment

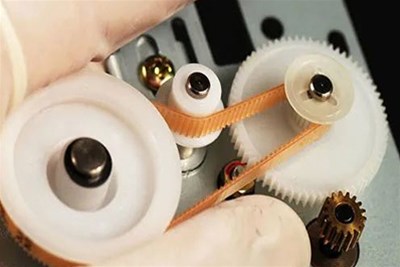

From the silent operation of household appliances, to the precise transmission of industrial equipment, to the flexible movements of smart toys, plastic gears have become the "core transmission unit" of various types of equipment with their unique advantages of lightweight, wear-resistant, low noise, and cost-effectiveness. A high-quality plastic gear directly determines the operating efficiency, service life and user experience of the equipment. As a professional plastic gear manufacturer, Dongguan Kunpeng Mechanical and Electrical Co., Ltd. is deeply involved in the field of transmission components. With "precision molding, stability and durability, and on-demand customization" as its core, it focuses on the R&D, production and supply of plastic gears, providing highly adaptable transmission solutions for various industries and helping equipment achieve efficient and stable operation.

Core Competencies: Kunpeng Plastic Gear’s “Four Major Performance Advantages”

Kunpeng Electromechanical abandons the industry pain points of traditional plastic gears that are "easy to age, have poor strength, and lack precision." Through raw material selection, process optimization, and structural design, Kunpeng Electromechanical has created a plastic gear product system with comprehensive performance, becoming the trusted choice of equipment manufacturers.

1. Blessed with high-quality raw materials, durability is greatly improved

We insist on using high-performance engineering plastics such as PA66, POM, PC, and PP. Some high-end products add glass fiber reinforcement, carbon fiber modification and other ingredients to increase the tensile strength of the gear by more than 40% and the impact toughness by 35%. After testing, it has a continuous operating life of more than 10,000 hours under normal temperature conditions, stable performance in high and low temperature environments from -30°C to 80°C, and does not become brittle or deformed. It is fully adapted to the needs of multiple scenarios such as household, industrial, and outdoor use.

2. Precision processing control, precise and stable transmission

Equipped with a high-precision CNC machining center, injection molding equipment and automated testing instruments, the gear module covers 0.1-5.0mm, the tooth profile error is controlled within ±0.01mm, and the cumulative tooth pitch error is ≤0.02mm, ensuring smooth meshing during the transmission process, without jamming or frustration. For the needs of precision equipment, the gear runout can be achieved ≤0.03mm, effectively improving the transmission accuracy of the equipment and reducing energy loss.

3. Low-noise and silent design, suitable for comfortable scenes

By optimizing the tooth profile curve (using involute, arc tooth profile, etc. designs) and surface fine grinding process, the noise during gear meshing is controlled below 45 decibels, which is much lower than traditional metal gears and ordinary plastic gears. In noise-sensitive scenarios such as household appliances, medical equipment, and office equipment, it can greatly improve comfort and solve the problem of equipment operation noise.

4. Corrosion and corrosion resistance, adaptable to complex working conditions

Plastic gears are inherently resistant to chemical corrosion and can withstand corrosion from common media such as grease, weak acids, and weak alkali, without the need for additional anti-rust treatment. In humid or corrosive environments such as food processing equipment, chemical auxiliary equipment, and bathroom hardware, the service life is 2-3 times longer than that of metal gears, reducing equipment maintenance costs.

Product matrix: full category coverage, adapting to diverse transmission needs

As a professional plastic gear manufacturer, Kunpeng Electromechanical has created a diversified product system based on the transmission characteristics of different equipment, covering standard parts and customized parts, realizing "one equipment, one adaptation solution."

1. Universal standard plastic gear series

Including spur gears, helical gears, bevel gears, internal gears and other basic styles, the module number is 0.1-5.0mm, the number of teeth is 5-100 teeth, and the aperture diameter is 1-50mm. Focusing on high cost performance and fast delivery, it is suitable for common scenarios such as household appliances (washing machines, air conditioners, soymilk machines), office equipment (printers, copiers), power tools, etc. It has sufficient stock in stock and can be shipped immediately after placing an order.

2. Precision equipment plastic gear series

Focusing on high-end transmission needs, we launch products such as micro precision gears, reduction gear sets, and self-lubricating gears. The minimum module of the micro gear is 0.1mm, which is suitable for smart wearable devices, medical instruments (blood glucose meters, sphygmomanometers), precision instruments and other scenarios; the reduction gear set integrates a multi-gear transmission design with precise transmission ratio and can be directly adapted to small motors, reducing assembly costs for equipment manufacturers.

3. Special working condition plastic gear series

Functional gears are customized for special scenarios, including high-temperature-resistant gears (adapted to ovens and industrial ovens), low-temperature-resistant gears (adapted to cold chain equipment), waterproof gears (adapted to bathroom equipment, underwater instruments), and anti-static gears (adapted to electronic workshop equipment). Through raw material modification and structural optimization, the gears are ensured to drive stably under special working conditions.

4. Gear components and supporting series

Provide gear shafts, gear boxes, synchronization wheels, transmission belts and other supporting components to achieve one-stop supply of "gears + accessories". The gearbox adopts a modular design, and gear sets with different transmission ratios can be combined according to equipment needs, adapting to the motor power range of 5W-500W, providing equipment manufacturers with a complete transmission solution.

Manufacturer strength: full process guarantee from production to service

Kunpeng Electromechanical relies on a complete production system, strict quality control standards and considerate service capabilities, and uses the advantage of direct supply from manufacturers to solve procurement and application pain points for customers and improve cooperation efficiency.

1. Large-scale production, stable and efficient supply

It has a modern production base covering an area of 6,000 square meters, equipped with 8 special production lines for plastic gears, using automated injection molding, precision processing and assembly equipment, with a daily production capacity of 500,000 pieces and an annual production capacity of over 150 million pieces. Supports small batch trial production (minimum order of 100 pieces) and large batch orders (millions of orders accepted), regular standard parts are shipped within 24 hours, and customized parts are delivered accurately in 3-7 days depending on the complexity of the solution.

2. Full-process quality control, reliable and controllable quality

Establish a full-chain quality control system of "raw material testing-production process monitoring-finished product inspection", equipped with professional equipment such as tooth profile measuring instruments, tensile testing machines, and fatigue life testing machines. Each batch of gears must undergo 12 core indicators such as dimensional accuracy, tooth profile deviation, strength testing, and wear resistance. The factory pass rate is stable at more than 99.8%, and each batch comes with a detailed quality report.

3. Outstanding customization capabilities and accurate matching of needs

Equipped with a professional mechanical design team, we can provide "one-on-one" customized services based on equipment drawings, samples or transmission parameters (speed, load, installation space) provided by customers. We follow up the whole process from gear structure design, raw material selection, mold development to sample trial production, such as customizing lightweight gear sets for intelligent robots and customizing food-grade plastic gears for food machinery to accurately solve the pain points of personalized transmission.

4. Direct service from the manufacturer, significant cost-effective advantage

Adopting the "R&D-production-sales" integrated model, eliminating intermediate circulation links and directly providing customers with factory-priced products. At the same time, it provides free sample testing, technical consultation, installation guidance and other value-added services to help customers optimize transmission solutions, such as reducing equipment energy consumption through gear parameter adjustment, further reducing overall costs for customers.

Industry application: Plastic gears empower equipment upgrades in thousands of industries

With stable performance, flexible adaptability and considerate service, Kunpeng Electromechanical's plastic gears have deeply served many core fields and become long-term partners of many equipment manufacturers.

1. Household appliances field

We provide plastic gears for washing machine transmission systems, air-conditioning indoor unit fans, soy milk machine stirring mechanisms, microwave turntable components, etc., with low noise and lightweight features to enhance the experience of using home appliances and reduce the manufacturing costs of home appliances.

2. Industrial automation field

It is suitable for assembly line conveyor belts, small robot joints, automated sorting equipment, sensor transmission mechanisms, etc. The stable transmission characteristics of precision gears ensure the continuous and efficient operation of industrial equipment and reduce downtime and maintenance time.

3. Medical and health field

We provide food-grade, low-noise plastic gears for blood pressure monitor air pumps, blood glucose meter testing mechanisms, rehabilitation equipment transmission components, medical infusion pumps, etc., which comply with the health standards of the medical industry and ensure accurate operation and safe use of equipment.

4. Consumer electronics and smart device fields

Serving smart watch crown transmission, small drone gimbals, electric toy joints, smart home control mechanisms, etc., the small size and precise transmission of micro precision gears help smart devices become thinner, lighter and more versatile.

5. Automobile and transportation fields

We provide temperature-resistant and wear-resistant plastic gears for automotive interiors (air-conditioning outlets, window lift mechanisms), vehicle navigation buttons, new energy vehicle charging gun transmission components, etc., which comply with automotive industry standards and improve the reliability of vehicle-mounted equipment.

Kunpeng Electromechanical: Be a reliable partner in the transmission field with professional strength

Dongguan Kunpeng Mechanical and Electrical Co., Ltd. is located in the core area of Dongguan's mechanical and electrical industry. It has 10 years of experience in the research and development and production of plastic gears. It is a comprehensive enterprise integrating R&D, production, sales and service. The company has established a complete quality management system. With the advantages of "stable quality, strong adaptability, and considerate service", the company has become a long-term partner of many equipment manufacturers in the Pearl River Delta and surrounding areas. Its products are exported to many provinces and cities across the country, and it has accumulated a good reputation in the field of transmission components.

- Previous:Plastic gear transmission features and concepts

- Next:Already the last article